DN pipe size charts provide standardized measurements for pipe diameters, wall thicknesses, and schedules in metric units. They are essential for engineering projects, ensuring compatibility and safety.

1.1 What is DN (Diamètre Nominal)?

DN, or Diamètre Nominal, is a metric system for standardizing pipe sizes, based on the internal diameter of pipes. It ensures compatibility and consistency in engineering and construction, adhering to international standards like ISO. DN is widely used globally, particularly in Europe, to specify pipe sizes accurately for safety and efficiency.

1.2 Importance of Pipe Size Charts in Engineering

Pipe size charts are crucial for ensuring accurate sizing, flow rates, and pressure capabilities in engineering projects. They help engineers select the right materials, comply with standards, and maintain system compatibility. This precision is vital for safety, efficiency, and cost-effectiveness in plumbing, HVAC, and industrial piping systems.

1.3 Overview of DN Pipe Size Chart PDF

A DN Pipe Size Chart PDF outlines pipe dimensions in millimeters, including outer diameters, wall thicknesses, and schedules. It serves as a quick reference for engineers to select pipes that meet project requirements, ensuring accuracy and compliance with international standards for various applications.

Understanding DN and NPS (Nominal Pipe Size)

DN (Diamètre Nominal) and NPS (Nominal Pipe Size) are global standards for pipe sizing. DN is metric, measured in millimeters, while NPS is imperial, measured in inches, ensuring compatibility across systems.

2.1 Definition of Nominal Pipe Size (NPS)

Nominal Pipe Size (NPS) is a standard measurement system in inches used to identify pipe sizes. It designates the diameter of pipes, fitting, and components, ensuring uniformity in engineering and construction projects, with sizes ranging from 1/8 inch to 30 inches for seamless compatibility across industries and applications.

2.2 Differences Between DN and NPS

DN (Diamètre Nominal) measures pipe diameters in millimeters, while NPS (Nominal Pipe Size) uses inches. DN is commonly used in metric countries, whereas NPS is standard in the U.S. Both systems classify pipe sizes but differ in units and regional adoption, requiring conversion for international projects and compatibility between systems.

2.3 Conversion Between DN and NPS

Conversion between DN and NPS involves understanding their units: DN is in millimeters, while NPS is in inches. To convert DN to NPS, divide the DN value by 25.4. For NPS to DN, multiply the NPS value by 25.4. Conversion charts or tables are essential for accuracy, ensuring compatibility in international piping standards and minimizing errors.

How to Read a DN Pipe Size Chart

Identify the DN, which corresponds to the nominal diameter in millimeters. Locate the outer diameter (OD) and wall thickness for each schedule, ensuring compliance with project requirements.

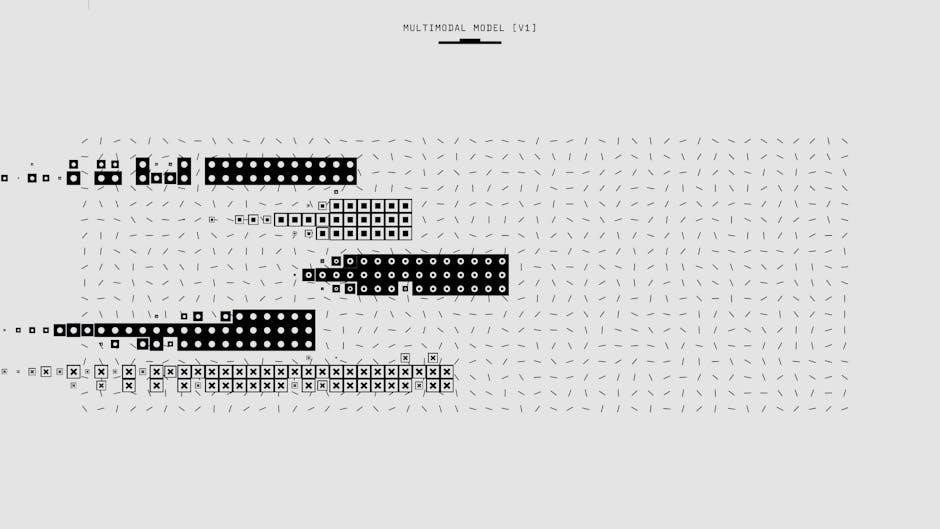

3.1 Key Components of the Chart

The chart includes nominal diameter (DN), outer diameter (OD), wall thickness, and schedules. These elements are organized in a table format, allowing users to quickly look up specific pipe sizes and specifications, ensuring accurate selection and compliance with industry standards.

3.2 Interpreting Dimensions and Schedules

Interpreting DN pipe size charts involves understanding nominal diameter (DN), outer diameter (OD), wall thickness, and schedules. The chart organizes these dimensions in a table format, allowing users to quickly identify pipe sizes, wall thicknesses, and schedules for specific applications, ensuring accurate pipe selection and compliance with engineering standards.

3.3 Practical Examples of Chart Interpretation

For instance, a DN 50 pipe corresponds to an outer diameter of 60.3 mm and a wall thickness of 3.65 mm for SCH 40. Similarly, DN 15 translates to NPS 1/2″, with an OD of 21.3 mm. These examples help engineers quickly identify pipe dimensions for specific applications, ensuring accurate system design and installation.

Common Applications of DN Pipe Size Charts

DN pipe size charts are widely used in plumbing, HVAC systems, industrial piping, oil and gas industries, and construction projects to ensure accurate pipe sizing and compatibility.

4.1 Use in Plumbing and HVAC Systems

DN pipe size charts are crucial in plumbing and HVAC systems for selecting pipes that meet flow rate and pressure requirements. They ensure system efficiency, reduce friction losses, and prevent leaks, making them indispensable for designers and engineers working on residential and commercial projects.

4.2 Role in Industrial Piping and Construction

DN pipe size charts are vital in industrial piping and construction for selecting pipes that meet material, strength, and dimensional requirements. They ensure compliance with international standards, facilitate system design, and optimize performance, making them indispensable for engineers and contractors in large-scale industrial projects.

4.3 Application in Oil and Gas Industries

DN pipe size charts are extensively used in the oil and gas industries for precise piping system design. They ensure pipes meet high-pressure, high-temperature, and corrosion-resistant requirements, critical for drilling, transportation, and processing operations. Charts help in selecting appropriate materials, wall thickness, and schedules, ensuring safety and efficiency in demanding environments.

Factors Influencing Pipe Size Selection

Pipe size selection is influenced by flow rate, pressure requirements, material properties, wall thickness, and compliance with international standards. These factors ensure optimal performance and safety in piping systems.

5.1 Flow Rate and Pressure Requirements

Flow rate and pressure requirements are critical in selecting pipe sizes. Higher flow rates demand larger diameters to minimize friction and pressure drop, ensuring efficient fluid transport. Pressure rating must match the system’s maximum pressure to prevent failure, with charts providing guidelines for optimal pipe sizing based on these parameters.

5.2 Material and Wall Thickness Considerations

Material type and wall thickness are vital for pipe durability. Thicker walls offer higher strength and resistance to internal pressure, while thinner walls reduce weight and cost. DN charts specify wall thicknesses for materials like steel, PVC, and copper, ensuring compatibility with fluid types and environmental conditions.

5.3 Compliance with International Standards

Adhering to international standards ensures global compatibility and safety. DN pipe size charts align with ISO and DIN specifications, providing uniform measurements for pipes and fittings. Compliance guarantees interchangeability, quality, and reliability across industries, meeting regulatory requirements for diverse applications and markets worldwide.

Converting DN to Inches and Vice Versa

Converting DN to inches requires precise charts or formulas to ensure accuracy. Use reliable conversion tables for exact metric to imperial measurements in engineering applications.

6.1 Step-by-Step Conversion Guide

Begin by identifying the DN or NPS value from the chart. Use the conversion formula: DN = 25(NPS) + 50. For inches to DN, apply DN = NPS * 25 + 50. Verify using a reliable conversion table to ensure accuracy in measurements for engineering applications.

6.2 Using Conversion Tables for Accuracy

Conversion tables provide precise mappings between DN and NPS, ensuring accurate measurements. They list equivalent sizes, wall thicknesses, and schedules, minimizing errors. Reliable tables are available in DN pipe size chart PDFs, offering a quick reference for engineers. Always verify with standardized charts to maintain consistency and compliance in pipe sizing applications.

6.3 Avoiding Common Conversion Errors

Common errors include misinterpreting DN as inches or NPS, leading to incorrect sizing. Always use standardized DN pipe size charts to ensure accurate conversions; Verify units and cross-reference measurements to avoid mismatches. Double-checking with reliable sources prevents errors and ensures system compatibility and functionality.

Pipe Wall Thickness and Schedules

Pipe wall thickness and schedules specify the pipe’s internal diameter and strength. Common schedules like SCH 40 and SCH 80 are crucial for engineering applications, ensuring compliance with international standards.

7.1 Understanding Pipe Schedules (e.g., SCH 40, SCH 80)

Pipe schedules define wall thickness relative to the pipe diameter. SCH 40 and SCH 80 are common designations, with SCH 80 being thicker for higher pressure applications. These schedules determine the strength and durability of pipes in various systems, ensuring proper material selection for safe and efficient operations across industries.

7.2 Relationship Between DN and Wall Thickness

DN (Diamètre Nominal) represents the nominal diameter of a pipe in millimeters, while wall thickness is specified by schedules (e.g., SCH 40, SCH 80). As DN increases, the range of possible wall thicknesses expands, ensuring pipes meet specific pressure and durability requirements. Charts provide precise values for each DN, aiding accurate pipe selection.

7.3 Standard Wall Thickness for Common Pipe Sizes

Standard wall thicknesses for common DN sizes are specified in charts, ensuring consistency across applications. For example, DN 50 pipes typically have wall thicknesses ranging from 2.9mm (SCH 10) to 5.3mm (SCH 30). These standards ensure pipes meet durability and pressure requirements while maintaining compatibility with fittings and valves.

How to Use DN Pipe Size Charts for Pipe Selection

Use DN charts to match pipe sizes with project requirements, ensuring correct DN, schedule, and compatibility with fittings and systems for optimal performance and safety.

8.1 Determining the Correct DN for Your Application

To determine the correct DN, assess flow rate, pressure, and system requirements. Refer to the DN chart, matching the nominal diameter with the needed specifications. Ensure compatibility with fittings and valves for seamless integration. This step ensures optimal performance and safety in piping systems.

8.2 Matching DN with Fittings and Valves

Always ensure DN pipe sizes align with fittings and valves to maintain system integrity. Use the DN chart to verify compatibility, preventing leaks or installation issues. Proper matching ensures optimal flow rates and pressure handling, while adhering to international standards for reliable performance in industrial and plumbing applications.

8.3 Verifying Compatibility with Existing Systems

Verify DN pipe compatibility with existing systems to ensure seamless integration. Cross-reference the DN chart with current system specifications, checking diameters, wall thicknesses, and schedules. This prevents mismatches, ensuring efficient operation and compliance with safety standards. Proper verification minimizes installation challenges and maintains system performance across industrial and construction applications.

Dimensional Tolerances in DN Pipe Sizing

Dimensional tolerances ensure pipes meet specified standards, minimizing deviations in diameter and wall thickness. This precision is critical for proper fitting and system performance in industrial applications.

9.1 Understanding Tolerances in Pipe Manufacturing

Tolerances define acceptable deviations in pipe dimensions, ensuring consistency. They apply to outside diameters, wall thicknesses, and lengths, critical for proper fitting and performance. Standards like ISO or API regulate these variances, ensuring pipes meet design specifications and operational safety. Ignoring tolerances can lead to installation issues or system failures.

9.2 Impact of Tolerances on Pipe Fittings

Tolerances directly affect pipe fitting compatibility. Excessive variations in pipe dimensions can cause loose connections, leaks, or installation difficulties. Tighter tolerances ensure precise fits, minimizing potential failures. Proper understanding of tolerances helps in selecting fittings that align with pipe specifications, maintaining system integrity and performance.

9.3 Ensuring Precision in Pipe Size Selection

Ensuring precision involves consulting DN charts, verifying specifications, and adhering to international standards. Proper alignment of DN with NPS and wall thickness ensures compatibility. Using digital tools or conversion tables enhances accuracy, preventing sizing errors. Cross-referencing with manufacturer guidelines guarantees optimal fitment and performance in piping systems.

Downloading and Using DN Pipe Size Chart PDF

Download DN pipe size charts from reliable sources like engineering websites or manufacturer portals. Print or save the PDF for easy reference during project planning and execution.

10.1 Sources for Reliable DN Pipe Size Charts

Reliable DN pipe size charts can be sourced from reputable engineering websites, manufacturer portals, and industry standards organizations. Websites like SSM Alloys, Atlas Steels, and piping standards authorities provide accurate and comprehensive charts for download, ensuring compliance with international piping standards and specifications.

10.2 Printing and Referencing the Chart

Print the DN pipe size chart on high-quality paper for clear visibility of dimensions and schedules. Laminate it for durability and easy reference. Ensure the chart is scaled correctly during printing to maintain accurate measurements. Refer to it regularly during project planning and piping installations for precise pipe size selection and verification of specifications.

10.3 Integrating the Chart into Project Planning

Integrate the DN pipe size chart into project planning by using it to select compatible pipes, fittings, and valves. Cross-reference schedules and dimensions to ensure system integrity. Use the chart to visualize pipe layouts and verify compliance with design specifications. Share it with teams for collaborative planning and include it in project documentation for future reference.

Common Mistakes in Using DN Pipe Size Charts

Common mistakes include misinterpreting DN and NPS, ignoring wall thickness, and overlooking tolerances. Ensure accuracy by cross-referencing schedules and standards to avoid system incompatibilities and safety risks.

11.1 Misinterpretation of DN and NPS

Misinterpreting DN (Diamètre Nominal) and NPS (Nominal Pipe Size) can lead to sizing errors. DN is metric, while NPS is imperial, often causing confusion. Mixing these systems can result in incompatible pipe fittings and incorrect flow rates. Always verify measurements using conversion charts to ensure accuracy and avoid system malfunctions.

11.2 Ignoring Wall Thickness and Schedules

Ignoring wall thickness and schedules can lead to system incompatibility and safety risks. Wall thickness determines pipe strength, while schedules like SCH 40 or SCH 80 specify thickness standards. Overlooking these factors can result in pipes failing under pressure or not fitting properly with fittings and valves, causing leaks or system malfunctions.

11.3 Overlooking Tolerances and Standards

Overlooking tolerances and standards can compromise system integrity. Tolerances ensure dimensional consistency, while standards like ASME B36.10 provide specifications for pipe dimensions. Ignoring these can lead to misalignment, leakage, or structural failure, emphasizing the importance of adhering to international standards for reliable and safe piping systems.

DN pipe size charts are essential tools for accurate pipe sizing, ensuring system compatibility and compliance with international standards. They streamline engineering processes, enhancing efficiency and reliability in various industries.

12.1 Summary of Key Takeaways

This guide provides a comprehensive understanding of DN pipe size charts, focusing on their role in pipe selection, conversion between DN and NPS, and factors influencing size selection. It highlights applications in plumbing, HVAC, and industrial piping, emphasizing compliance with international standards for safety and efficiency in system design and installation.

12.2 Best Practices for Using DN Pipe Size Charts

Always use reliable charts for accurate sizing, ensuring compatibility with fittings and valves. Verify dimensions against international standards and refer to updated versions. Cross-check with manufacturer specifications and understand schedules for wall thickness. Regularly update charts to align with industry advancements and compliance requirements for optimal system design and performance.

12.3 Future Trends in Pipe Sizing Standards

Future trends include digitalization of DN charts, integration with CAD software, and AI-driven sizing tools. Enhanced sustainability standards and material innovations will shape pipe sizing. Global harmonization of DN and NPS standards is expected, ensuring seamless international collaboration and compliance in engineering and manufacturing sectors.